by Art Merrill | Contributing Editor

by Art Merrill | Contributing Editor

On a strictly practical level, to successfully handload your own ammunition you could simply use the smokeless powders in the amounts called for in your reloading manual and never need to know anything more about them. But the same impulse that makes us DIY in the first place also drives our desire to know why and how things work, so let’s take a closer look at smokeless powders.

Basic black

To understand where we are it’s important to see where we came from; today’s smokeless powders got their start around 142 AD in China as gunpowder, which we now call blackpowder, based on its appearance. Blackpowder is a mechanical mixture of potassium nitrate, charcoal and sulfur in an ideal ratio of 74%, 15.5% and 10.5% respectively. There was a “brown” or “cocoa” powder that appeared about the same time as smokeless powder (1880s) that utilized only about 3% sulfur and was nearly as powerful as single-base smokeless powders, but the latter immediately eclipsed it and today brown powder is unknown.

To understand where we are it’s important to see where we came from; today’s smokeless powders got their start around 142 AD in China as gunpowder, which we now call blackpowder, based on its appearance. Blackpowder is a mechanical mixture of potassium nitrate, charcoal and sulfur in an ideal ratio of 74%, 15.5% and 10.5% respectively. There was a “brown” or “cocoa” powder that appeared about the same time as smokeless powder (1880s) that utilized only about 3% sulfur and was nearly as powerful as single-base smokeless powders, but the latter immediately eclipsed it and today brown powder is unknown.

A “semi-smokeless” powder—actually a mixture of black and smokeless powders—appeared in .22 Rimfire cartridges in the 1920s, but was discontinued within a decade because it had no real advantages over smokeless powders and its disadvantages included being corrosive and expensive.

Going smokeless

For all but the smallest rifle cartridges, rifle powders typically have extruded granules, shown here enlarged. L-R are IMR-4350, H4831SC and RL-15.

Smokeless powder was born a military secret in 1884 as Poudre B, the brainchild of French chemist Paul Vieille. By 1886 the French Army fielded the first smokeless powder cartridge, the 8x50Rmm Lebel, built on a modified 11mm Gras blackpowder cartridge case. Three years later the Swiss 7.5×55 Schmidt-Ruben became the first cartridge designed from the outset for smokeless powder.

The power and burning efficiency of smokeless powder is quantum leaps ahead of blackpowder, sending bullets at two and three times the velocity as blackpowder without the attendant smoke and corrosive residues. Smokeless powder revolutionized warfare arguably as much as did the invention of firearms.

Handloaders are concerned with only two types of smokeless powders, single-base and double-base. Of the other two types, bulk powders (for shotshells) are no longer manufactured and triple-based powders with nitroguanidine are expensive and not available to handloaders.

Single-base powders have nitrocellulose as the main ingredient; double-base powders use both nitrocellulose and nitroglycerine. What this means to us is that, compared to double-base powders, single-base powders cause less bore erosion because of their lower burning temperature (about 4000°F vs 5600°F). They are less susceptible to environmental temperature changes and they are better at burning progressively (more on that in a moment). The addition of nitroglycerine to double-base powders makes them significantly more powerful than single-base powders, so we see smaller charges of double-base pistol powders than those of single-base powders used in rifle cartridges.

Pistol cartridges may use flake powders (Blue Dot on the left), but some ball powders, like W-296 on the right, can be used in pistol or small rifle cartridges.

All extruded powders (e.g. IMR-4350, VV N-140, etc.) are single-base and used in rifle cartridges. Ball powders are double-base and may be used in pistol cartridges or small rifle cartridges. Flake powders are for pistol cartridges and shot shells (flake and ball powders are so-named for the shape of their granules). Look closely at a single powder granule, and you may see it is perforated—that is, it has a hole in it—to aid progressive burning.

Besides burning more efficiently, cleanly and thoroughly than blackpowder, progressive burning is what made smokeless powders a game-changer in history and sent other nations in a frantic rush to catch up to the French in 1886.

That’s progress

The names and designations for powders can be logical or completely arbitrary. For example, “IMR” is the abbreviation for “Improved Military Rifle” and goes back more than a hundred years to when smokeless powders were still newfangled. Hodgdon’s H380 is so-named because while in development a charge of 38 grains produced one-hole groups in Bruce Hodgdon’s .22-250. Other names, such as Trail Boss or CFE (Copper Fouling Eraser), are simply marketing monikers. Most important to us is a powder’s burning rate.

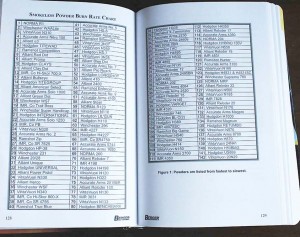

Reloading manuals list powders by their burning rate. The Berger Bullets manual lists 142 powders, from fastest to slowest.

Progressive burning increases gas production, and gas is what drives bullets down the bore. Imagine a single granule of blackpowder burning in slow motion. As it burns from the outside inward, the surface area of the granule gets smaller; as the surface area shrinks it produces less gas. This is called degressive burning. Now watch a granule of progressive smokeless powder burn. The granule of progressive powder continues to output maximum gas production even as it shrinks; it accomplishes this via physical geometry (sticks, balls, flakes, holes) and/or deterrent coatings that control the burning rate.

Burning rate is of interest to handloaders, and you will find a table in the front of your reloading manual that lists powders in order of their burning rate. As you progress in your handloading and wish to experiment with your own ideas, that table of burning rates will help keep you out of trouble: it’s critically important to match a powder’s burn rate to specific parameters of case volume and bullet weight to prevent overpressure or other problems.

Properly stored, powders can last for decades. But inherited cans of already opened powder may not contain what’s on the label—the previous owner might have put some other powder in it or mixed different powders together.

Generally, powders with slower burning rates are for larger cases and heavier bullets, and faster powders are best suited for smaller cases and lighter bullets. But the word “relative” is very important here because even when loading a single type cartridge—say, .30-06, a single powder is not going to be optimum for all bullet weights. That is, light 100-grain bullets will generally perform better in the .30-06 with relatively faster powders, compared to heavy 220-grain bullets that will do better with relatively slower powders. “Relatively” faster or slower refers to a small range of powders from that burn rate chart appropriate for the .30-06, and does not include the entire gamut of powders from the fastest pistol powders to the slowest for .50 BMG.

Barrel length is another factor in powder burning rate. As an example, I watched a gentleman shoot milsurp .30 Carbine ammo in his handgun; the muzzle flash caused by the comparatively slow powder burning outside the muzzle was visible in bright sunlight. On the other hand, powders that are totally consumed too soon in the barrel do not provide maximum benefit. In an ideal world the last vestige of powder would burn just as the bullet reaches the muzzle; this is why magnum calibers typically use the slowest powders and magnum rifles typically have long barrels, and why pistol calibers use double-base powders in short barrels.

Surprisingly, the reality of physics is far from our ideal: with even the most efficient load our firearms convert only about 30% of smokeless powder’s potential energy into kinetic energy. The rest is lost in heat transfer to the barrel, friction and unused energy escaping at the muzzle (gas escaping ahead of the bullet).

Character counts

Powders have other characteristics important to handloaders. We may want to make very mild loads, but there is a lower limit to how little powder we can charge in a case before we run into problems (misfires, erratic bullet flight and an alarming phenomenon called “detonation”). Using a comparatively dense powder, one that requires a larger charge to get the same performance as more efficient powders, may be a solution.

[pullquote align=”right” cite=”” link=”” color=”#FFFF99″ class=”” size=””]

Additional Powder Facts

Smokeless powders also contain other chemicals, such as stabilizers (dyphenalimine) for long shelf life; anti-static coatings (graphite) to prevent static electricity; ID tagants (colored tags mixed in with flake powders such as Red Dot and Blue Dot); anti-copper fouling agents (tin); and solvents. One of the latter is often acetic acid—vinegar. You can perform an unscientific “sniff check” of old smokeless powders: if it smells like vinegar, it has deteriorated and manufacturers caution against using it.

Contrary to popular misconception, smokeless powders are NOT explosives, they are propellants. The difference is not just semantics, it is in science defining the physics of their behaviors. Explosives detonate in microseconds (millionths of a second) and can produce nearly 4,000,000psi, making them unsuitable for firearms. Propellants burn far slower, in milliseconds (thousandths of a second) and produce up to 100,000psi, though maximum breech pressures in firearms are typically only slightly more than half that (62,000psi for the .30-06, for example).

[/pullquote]

Alliant and Hodgdon both make powders that leave less fouling in your bore, important to precision shooters and high-volume shooters. For long range precision shooters and hunters who work up handloads in the hot summer but hunt in cold weather, some powders are far less sensitive to temperature extremes (which will affect accuracy).

Sometimes we may prioritize avoiding simple exasperation by choosing a powder that flows or “meters” easily through our powder measure. Ball and flake powders meter well, but the comparatively long granules of extruded rifle powders can hang up in a powder measure, which gave rise to Hodgon’s line of SC—“Short Cut”—powders. The SC powders are identical to their parent powders of the same designation; that is, H4831SC is H4831 but with shorter granules, and the load data for the two powders are directly interchangeable. Hodgdon’s “Extreme” line of rifle powders also have shorter powder granules.

Which brings us to next month’s subject: measuring powder charges.