by Art Merrill | Contributing Editor

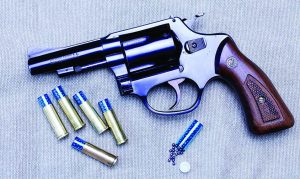

A small .38 revolver with shotshells makes an excellent hiking companion.

The 38 Special remains ubiquitous, but there’s one unique load that gets little attention: the shotshell.

In addition to dealing with rattlesnakes under the porch steps, handgun shotshells are also useful for up-close vermin of rat size—or even rabid-dog size, with larger shot. Loaded and used properly, handgun shotshells can dispatch rats in a barn or shed without causing undue damage to the structure itself. Did you know that during WWII the government issued .45 ACP shotshells to air crewmen for foraging in a shot-down survival situation? Handgun shotshells are candidates for entertainment and experiment, and those latter reasons sum up a major aspect of handloading.

Simple plastic

Seat shot capsules deep enough to permit proper cylinder rotation.

The two methods of building 38 Special shot shells is to either use a combination of wads, one between the powder and shot and the other on top of the shot to close the end of the cartridge case, or to utilize a closed hollow plastic capsule in place of a bullet to contain the shot. The first method limits the amount of shot used because it must all fit inside the case below the mouth. The plastic capsule extends beyond the case mouth to allow room for roughly twice as much shot, equating to higher target hit probability.

The wad method is a bit fussy and slower compared to the plastic cup, but it has its own nearly endless options for experimenting, such as using cast bullet gas checks, felt cap & ball over-powder wads or your own ideas for wads, shot cups and weather sealing. Here, let’s get the beginning 38 Special shotgunner started with the more simple plastic capsule. Speer makes the shot capsules, and there may be other manufacturers, as well. Do note that plastic shot capsules aren’t durable enough for magazine loading in lever action rifles, nor are shot shells completely safe for guns with ported compensators.

Choosing components

Seat shot capsules with finger pressure and finish up in the seating/crimping die. The two knurls ID this as a full wadcutter case.

In shotgunning, we choose shot appropriate to the intended game and the expected distance to the target. To generalize, in handgun shotshells “long range” is maybe 15 feet; hit probability drops significantly much beyond that distance regardless of the number of pellets we launch due to the combination of short barrels and rifling that quickly throws shot patterns outward from center. Of course, the larger the shot size the fewer number of pellets will fit in the shot capsule; for this reason, you may find shot sizes #6 to #9 your top choices, with #9 probably the better choice for rats or pigeons inside structures and #6 for vermin outdoors.

There isn’t a whole lot of load data out there for 38 Special shotshells, compared to bulleted loads. The most commonly known load is right off the Speer box of shot capsules, 5.5 grains of Unique and #9 shot. Generally speaking again, you may find better/tighter patterns with lesser charges, especially with smaller shot sizes. We don’t need special dies for loading these shotshells but you may need to experiment with your technique a bit.

Salvaged shot from old shotgun shells is cheap ammo.

Though I haven’t yet sectioned a case to see for myself, I’ve read that many 38 Special cases loaded at the factory with full wadcutters have a sharper angle at the web—where the inside of the case tapers into the case head—than do cases not intended for these bullets. This lesser taper supposedly permits seating the shot capsule more easily than do 38 Special cases not intended for full wadcutters. I have, indeed, noted that I can press the capsule further into the full wadcutter case and with less chance of breakage, but I’ve also experienced cases that stop the capsule from easily entering any further than the lowest knurl. You can visually ID these full wadcutter cases by the two circumferential rings, or knurls, left on the case by factory crimping.

Clean, resize, expand case mouths, seat primers and charge cases as usual in preparation to receive the shot capsules. Fill the capsules with your chosen shot and snap the end cap in place. Then using finger pressure, push the cap end of the capsule into the prepared case as far as possible; finish with the seating die to an overall length (OAL) of 1.5”.

No-crack crimping

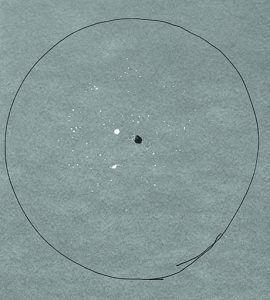

5.0 grains of Unique put all #8 pellets in a fairly round 10” pattern at 10 feet. The large hole is from the shot shell’s endcap.

Your die set likely came with two seater plugs, one for round nose bullets and the other for flat meplats; with either of these, the outer circumference of the seater is the only part that touches the shot capsule (because the center of the capsule mouth is recessed slightly), so either should work. To avoid breaking the plastic capsule, work the press handle slowly when seating. If the plastic capsules break during final seating, double check that case mouth expansion is adequate. Chamfering the inside edge of the case mouth may help, as well.

We need to crimp plastic shot capsules in place for the same reason as for bullets, to prevent them backing into or out of cases under recoil, handling or transportation. The 38 Special, headspacing on the rim, gets a roll crimp from the seater die. A too-tight roll crimp can crack or break the plastic capsules, so a taper crimp is preferable. That’s the theory, but in practice and in loading shotshells for this article, my standard RCBS bullet seating die applying a roll crimp (and using the flat meplat seater plug) performed flawlessly—not one broken capsule. Simply adjust the die up or down in the press for appropriate roll crimp tension as you normally would with any bullet. If you’re absolutely set on having a taper crimp, a 9mm Luger seat/crimp die works. I ran a loaded cartridge to the top of the press stroke, removed the 9mm seating plug and screwed the die down until it touched the case mouth, then gave it a firm twist downward onto the case. That was crimp enough; set the lock ring and you’re good to go.

Loads for .38 Special

Shotshells

Speer plastic shot capsule

Lead shot, from #9 to #1*. A capsule loaded with #8 shot weighs, on average, 101 gr.

38 Special cases, preferably cases intended for full wadcutter bullets.

Case trim length: 1.155”

Cartridge OAL: 1.5”

Primer: Winchester Small Pistol

Powder: 5.5 grains Unique

With #9 shot, this load produces about 1058fps (Speer data).

Other suggested powders/charges:

5.0 gr. Unique

4.5.gr. Win 231

4.0 gr. IMR 700X

4.5 gr. Hodgdon HP 38*The Speer shot capsule, with an inside diameter of about .307”, can accept shot up to size #1 (0.30”) if not deformed. #2 shot (0.27”) may be the largest practical size.

Patterning the 38

The standard target for “patterning” shotguns is a piece of blank paper with a 40-inch circle; shoot at a mark in the center and then evaluate the number and distribution of pellets that struck inside the circle. Typical patterning distance runs from 20 to 40 yards. For testing the 38 Special shot shell, a 20-inch circle at 10 feet gives us more real-world information.

I loaded up a batch of shot cartridges using #8 shot salvaged from old shotgun shells and 5.0 grains of Unique; brass was a mixed bag of random stuff, including some full wadcutter cases. This load in a 4” barreled S&W M&P Model 10 revolver placed pellets in a fairly round 10” pattern. Incidentally, the plastic end cap tending to land pretty close to point of aim, and bits of shattered plastic capsule left ragged holes in the paper, though they didn’t completely penetrate the cardboard target backing.

Shot shells provide us with another facet of handloading, with plenty of room for testing our own ideas. It may arguably be safer than bullet handloads as light crimps and frangible projectiles probably keep pressures lower. Whether you’re new to handloading or the 38 Special is old hat to you, shotshell loading is a fun and educational pursuit.