by R.K. Campbell | Contributing Editor

Firearm cleaning is a process that prolongs the life of the barrel and other necessary parts used during firing. Neglecting this care and maintenance will cause the shooter to have a firearm that will not function at its utmost potential. Powder residue and carbon must be cleaned from the actions and chambers to ensure feed and fire reliability. Barrel fouling from copper, lead, and powder residues will throw off accuracy after only a few shots. Imagine what the build-up does to accuracy after a routine of not thoroughly cleaning the firearm. Even a quick once-over after every range trip without removing the leftover residuals will cause layers to start to form that will take tons of scrubbing to reverse.

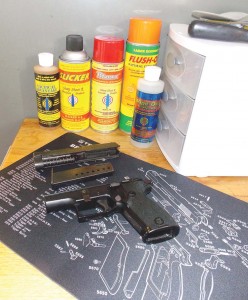

When work space is limited and air circulation at a premium, Sharp Shoot R Precision’s gun care products really shine.

By now, every gunowner knows the drill after the range. Grab the solvent, bore brushes, rags, patches and lubricant. Dip the bore brush in the solvent and scrub away until your heart is content. Run your dry patch and repeat if necessary. Now imagine all the scratches that the brush makes from the first day that you owned the gun up until the most recent cleaning. Over time, those scratches will affect accuracy. Sharp Shoot-R has revolutionized the cleaning process with odorless chemicals that do not require brushing.

Wipe-Out Brushless Bore Cleaner was designed to remove all of the burnt powder, carbon, and metal fouling from lead and copper to restore a firearm’s lost accuracy. Wipe-Out comes in an aerosol container with an adapter that fills the barrel with expanding foam cleaner from the muzzle. After a 60-minute resting period, simply run a dry cleaning patch through and check for any residual coloring. A grayish-black on the patch is from powder fouling. A navy blue color will be from copper fouling. Carbon will leave the patch a tannish-brown color. If the patch shows deep heavy colors, longer periods of soaking time will be required.

Wipe-Out was specially formulated to be safely utilized as a soaking agent that won’t damage firearms, unlike caustic cleaners with ammonia or acids. It also takes away the scrubbing from bore brushes that over time will scratch and mar the inside of barrel riflings. Along with making cleaning easier, Wipe-Out is also a rust inhibitor; it is non-flammable, and dissolves copper, bronze, and brass. It may safely be used on stainless, carbon steel, and even chrome-lined barrels without any damage. Modern gunstocks and modern paints are also safe with use; however, oil-type finishes such as shellac or varnish will be removed, so extreme care must be taken. Wipe-Out is stain-free for skin and clothing, although hands and skin should be washed after using the product. Wipe-Out is available in a 6-ounce aerosol can that is enough for around 75 different cleanings. It is safe to use in all rifles, pistols, shotguns, and black powder guns. It will also clean out muzzle brakes, flash hiders, and silencers. Because of its low PH and its odorless properties, it is safer to use than most acidic or petroleum based products.

Wipe Out Accelerator ‘supercharges’ the standard Wipe Out, while Maxx lubricant works well with all firearms. The author found these new products perform as advertised. The author tested Maxx lubricant in several training sessions with good results.

Wipe-Out will remove carbon, metal fouling, and powder residue, but not lead. As an alternative, No Lead Brushless Lead Remover is a way to clean firearms safely without harmful repetitive brushing, and it also wipes out easily just like the brushless bore cleaner. Lead deposits decrease accuracy by filling in the rifling and the scrubbing to remove this lead harms barrels over time. This unique cleaner turns from a clear red to a chalky grey color as the lead is dissolved. Once applied with a cleaning mop or a wet patch, a 20 minute rest dissolves the lead in the barrel. Once dissolved, a dry patch pushed through is all that is required. No Lead will remove the lead, but will not work on the other residuals such as carbon, burnt powder, and metal fouling. After removing the lead, Wipe-Out Brushless Bore Cleaner may be used to thoroughly finish cleaning the firearm.

As a lubricant for use after a deep cleaning of the firearm, Maxx Lubrication may be applied. Maxx is the new Mil-Spec Lubricant for the US military. Its moisture-displacing properties, neutral permittivity and superior corrosion protection barrier are a must after any cleaning job. Lubrication is important to firearm maintenance to ensure that all of the parts move properly with a minimum of friction. Without lubrication the firearm could seize, jam, or overheat and warp the frame or intricate parts. Along with lubrication, a rust inhibitor to protect from moisture and other elements keeps your firearms from turning for the worse.

After cleaning my hard use firearms and using Sharp Shoot R products after a hard training class, I find that they work as advertised and make life easier. For more information about these or any other Sharp Shoot R Precision Products, visit the Paola, KS, company’s website: sharpshootr.com, or phone them at 785-883-4444.