By James C. Fulmer | Past President, NMLRA

“Absolutely nothing is good enough if it can be made better. And better is never good enough if it can be made best.”

—Author Unknown

When you go to the Rice Barrel Company website the first thing you will see is that quote. I appreciated that quote because as a young Tool & Die Maker my seniors always told me the same “Once what you made leaves this shop, it will never be any better than it is now.”

Jason Schneider owns Rice Barrel Company now, and for years Jason and I would talk about me coming down to visit his shop in Mocksville, NC. I have been rifling barrels on an 18th century style rifling machine for several years and any pointers would help. Newly retired after 42 years of machine work, I finally had time for the visit.

This is a view of Rice Barrel Company’s Shop.

Arriving at Rice Barrel Company I met with Jason and he gave me some background about the company. Rice Barrel Co, Inc. was started years ago by LC Rice and his brother Liston Rice, along with their cousin David Rice. They also started the L & R Lock Company which, until I talked to Jason, I will admit that I didn’t know the R in L & R was for Rice. Jason was originally hired by the Rice Barrel company to be the head machinist and shop foreman. Jason eventually became the owner of the business.

Jason showed me the process in making the Rice Barrel. It starts at the front door of the 4,000 square foot shop. The 12L14 steel comes in to the shop as mostly 1-1/8” and 1¼” round stock. Each barrel blank is heat treated in an electric furnace to stress relieve. This procedure eliminates stress and warpage after machining, helping to control harmonic vibration and/or barrel whip. I learned early on as machinists that when machining steel on a mill, whatever you take off one side you need to take off the other. If you have a 2-inch piece of steel and want to make it 1 inch and you take the 1 inch from just one side of that piece it will look like a rocking horse. You need to take a half inch off both sides to help control the amount of stress put in the steel.

These breech plugs are ready to be hand fitted to barrels.

The barrels still in the round are drilled on a deep whole drill and machined between centers on a CNC milling machine. CNC means Computer Numerical Control. The beauty of a CNC mill, and especially in muzzle loading barrel making, is that once a barrel is made on the machine, the information is stored in the computer forever to make a contour. Over the years the more popular original barrels have been copied into the CNC mill computer so it can reproduce the barrel used by a Leigh, York, Lancaster, Bucks, or even barrels used by specific gun makers. Rice Barrel Company offers more swamp contoured barrels at this time because of this technology. His website (ricebarrels.com; phone: 336-492-2614) has a complete list of muzzle loading barrels and calibers available.

Jason cuts the rifling .016 deep on round bottom rifling and .012 deep on square bottom rifling. The cutter is a single cut cutter and is a traditional Springfield type rifling head with a single hook to cut each grove. Rifling a barrel is the fun part to me on barrel making and the easiest but most important part of the rifle’s accuracy. I have an 18th century style rifling machine which I rifle a barrel with a scraper style cutter and I only cut square bottom rifling .010-.012 deep. I will line up the cutter with .0015 pieces of paper one cut at a time until I get the .010-.012 deep rifling measurement over a lead slug driven through the barrel. It takes me and a helper about 12 to 14 hours to rifle one barrel. Actually it takes me almost a year as I start at Kalamazoo, MI, in March and end the rifling at Fort Roberdeau, PA, in October. I am demonstrating and talking across the country at 7 different events telling the history of rifling and promoting the National Muzzle Loading Rifle Association.

Left to right: the author standing with barrel makers Charlie Kinter, Rice Barrel Company owner Jason Schneider, Tyler Barringer and Austin Tilley.

There is a big difference between the 18th Century rifling machine and Jason’s machine. Designed by Rice themselves, the Rice Barrel Company built a one of a kind rifling machine. The rifling machine is a proprietary, infinitely variable, CNC rifling machine. I watched it run, and while I have been around machining my whole life, it is a beautiful piece of machinery to watch. Something else that Jason does is after the rifling has been cut, a carbide bore size die is pulled through the barrel to insure bore dimension for tight spots and loose spots in the barrel. It leaves the tops of the lands polished, which helps to eliminate the traditional lead lapping procedure.

Every barrel is hand fitted and timed for a breech plug. When I saw all the breech plugs he had in boxes in his shop, the first thing I asked was how many barrels you make a year. Rice Barrel Company’s 4,000-square-foot shop makes 2,000 barrels a year. Counting Jason, it is a 4-man shop that are all skilled in the art—no the science—of making muzzle loading rifle barrels. For the future, Jason plans on making Thompson Center Hawken drop-in barrels that will be available in different rifle twists and calibers. These will be complete but in the white, not having any bluing or browning on the barrels.

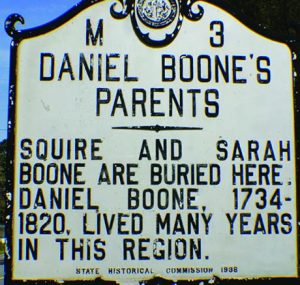

This is a photo of Daniel Boone’s parents’ grave site at Mocksville, NC.

While visiting Jason in Mocksville, NC, I asked about Daniel Boone and his family. I knew they had moved into the area in the 1750’s and much to my surprise, Squire and Sarah Boone, who are Daniel’s parents, were buried just down the road. Jason also asked if I was going to visit Old Salem. I said what is that? He looked at me in disbelief and proceeded to tell me it was an 18th century Moravian settlement that has been preserved just like Williamsburg, VA. It has cobblestone streets and craft shops and he went on to tell me I must visit Blake Stevenson who works in the T. Vogler Gunsmith Shop making muzzleloaders. Which I did and that will be another story.