by Art Merrill | Contributing Editor

So, you just bought an AR-15 with “556 NATO” stamped on the barrel; your load data manual doesn’t list 5.56 NATO but tells you its .223 Remington loads are safe for your AR-15. Or perhaps the data, such as Nosler’s online load data, lists both 5.56 NATO and .223 Rem, but loads for both cartridges are virtually identical.

What gives? Are the .223 Remington and 5.56 NATO cartridges really identical and interchangeable? Can you safely fire one in a rifle chambered for the other?

To summarize here at the beginning, direct orders from General Consensus permit firing .223 Remington cartridges in rifles chambered for 5.56 NATO, but it may be an invitation to frustration—and worse—to fire 5.56 NATO cartridges in rifles marked and chambered for .223 Remington. The General’s short answer is that the NATO version is loaded to somewhat higher chamber pressure, and the chambers of the two cartridges are not identical.

Putting on the pressure

Receivers marked for both cartridges should have the NATO chamber—if the barrel is original to the rifle.

The numbers General Consensus shows us are 55,000psi for .223 Rem and 62,000psi for 5.56 NATO. That’s good enough info to keep smart shooters out of trouble, but it isn’t an absolute truth. It’s just as correct to contradict that and say .223 Rem max allowable pressures are 62,000psi and for 5.56 NATO it’s 55,000psi. How can it be both ways? Confusion about absolute max pressures in .223 Rem and 5.56 NATO cartridges derive from differences in who is measuring the pressure. Because authorities who set the standards measure chamber pressure with differing methodologies, their results are very different.

The three major standardizing authorities are the Sporting Arms and Ammunition Manufacturers Institute (SAAMI) and the Commission Internationale Permanente pour l’Epreuve des Armes à Feu Portatives (CIP) for .223 Rem, and the North Atlantic Treaty Organization, whose method for testing 5.56 NATO is Electronic Pressure Velocity and Action Time (NATO EPVAT).

SAAMI testing utilizes a method in which, upon firing, the expanding case presses against a transducer that measures the internal case pressure indirectly; SAAMI’s maximum allowable pressure for commercial .223 is 55,114psi. The CIP method is to drill a hole in the case and directly measure the tapped-off gas pressure, with a max allowable 62,366psi for the .223. When taking into account their different methods, the two disparate pressures, it turns out, are really the same—that is, CIP’s 62,377psi is equivalent to SAAMI’s 55,114psi. Again, the difference in the numbers is due to the different testing methods; if they used identical methods they would obtain the same pressure reading.

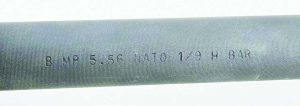

Check the AR’s barrel, not just the receiver, to determine its chambering. This heavy barrel is a Bushmaster chambered in 5.56 NATO with a 1:9 twist rate.

NATO EPVAT measures the time between primer ignition and when the bullet leaves the barrel and then compares that with standardized reference cartridges to infer chamber pressure. The NATO EPVAT maximum mean inferred pressure allowed is—surprise, surprise—equal to 55,000psi using the SAAMI method when fired in 5.56 NATO chambers.

Let’s toss this into the mix, too. The US military’s Small Caliber Ammunition Test Procedures (SCATP 5.56) methodology for 5.56 NATO is similar but not identical to SAAMI’s; their pressure limit, when fired in 5.56 NATO chambers, is 55,115psi.

So, why the concern over shooting 5.56 NATO in .223 Rem chambers? It’s that caveat, “when fired in 5.56 NATO chambers.” NATO chambers are slightly larger than .223 Rem chambers in several dimensions—again, because of differences between NATO and commercial standards. Those slight differences in chamber dimensions can significantly impact cartridge pressure.

Long and short of it

Bolt guns like this CZ 527 FS may also display chamber and twist rate info.

The 5.56 and .223 cartridges are like twins born together then gone their separate ways to military and civilian careers. They started life with short, comparatively light 52-gr. – 55-gr. bullets, the military version labelled the M193. Today’s NATO loadings are the SS109 and M855, which feature longer, heavier bullets. Modern 5.56 NATO chambered rifles have longer throats (or leade, the distance between the case mouth and the start of the rifling) than do rifles chambered for the .223 Rem.

Because the .223 Rem chamber has a shorter throat that is also slightly smaller in diameter and cut at a sharper angle than that of the 5.56 NATO, firing rounds like the SS109 and M855 in a rifle intended for the .223 Rem can increase pressures beyond even the already higher pressure military loading.

Shooting the .223 Rem in the longer-throated 5.56 NATO chamber does not present the same problem, but precision (accuracy) will likely suffer because the bullet has a longer “jump” to reach the lands. Chamber leade in the 5.56 is typically .162”, about twice that of the .223’s .085” leade.

Consider what

we’ve got:

- Chamber dimension affects chamber pressure; the “tighter” the chamber the higher the pressure, given an identical cartridge fired in both a “loose” and a “tight” chamber.

- 5.56 NATO is pressure tested and fired in chambers “loose” compared to commercial .223 chambers to yield normal 55,000psi equivalent pressures.

- .223 Rem is pressure tested and fired in chambers “tighter” than NATO chambers yet produce only that same 55,000psi equivalent pressures.

- Firing 5.56 in a comparatively “tighter” .223 chamber will increase the 5.56 cartridge’s chamber pressure. Because the 5.56 NATO already creates 55,000psi equivalent in a “loose” NATO chamber, the inference is that it must already be loaded, to some degree, to a higher pressure than .223 Rem. To know how much higher that pressure is, both cartridges must be measured using the same method and be fired in identical chambers.

That’s the physics. The practical reality is that firing 5.56 NATO in any given .223 Rem chamber may or may not cause overpressure signs such as difficult extraction, stuck cases, torn-off rims, blown primers or worse because the tolerance range for commercial chamber dimensions, as well as a particular rifle’s design, prevent an absolute, same-every-time result. But the matter is not one to dismiss and the wise person will heed the cautions from ammo and gun manufacturers (and SAAMI) who advise against firing 5.56 in the .223.

Other matters

Handloading eliminates any doubts or confusion about factory load labels.

When handloading for the AR-15 we must consider the working parameters of their gas systems. Powders must fall within appropriate burning rates to cycle the actions reliably without immediate or long-term damage while still obtaining desired bullet velocities. Sierra’s 5th Edition reloading manual is superior to others in featuring separate sections for bolt guns and AR-15s.

Note that the AR-15 platform easily separates into upper and lower assemblies, and that a receiver stamped, for example, “556 NATO” may actually have a .223 barrel or one for a completely different cartridge. Look on the barrel for a stamp indicating the caliber.

The longer throats of 5.56 chambers in the AR-15 can present a bit of a handloading conundrum. I once owned a bull barreled AR-15 varminter that shot 100-yd. one-hole groups with 69-gr bullets. But for that kind of precision its 5.56 chamber required seating the bullet so far out to start close to the lands that cartridges couldn’t fit in the magazine.

Choose bullets to match your rifle’s twist rate. Twist rates of 1:12 and 1:10 are adequate for precision shooting of the 50-55-gr. bullets, but rifles need a faster 1:9, 1:8 or 1:7 twist to stabilize longer, heavier 60-gr. to 90-gr. bullets. Shooters report mixed results with 55-gr. bullets in the 1:14 twist, which is why the Army increased M-16 twists from 1:14 to 1:12 for its M193 (today it’s 1:7 ½”), but 1:14’s can shoot 45-gr. bullets very well.

Older .223 rifles lacking a twist rate stamp likely (but not absolutely) have a slower twist; you can check twist rate by using a cleaning rod and a tight-fitting patch.

The AR-15/5.56/.223 matter exemplifies the independence of the handloader not being limited to guessing at or accepting simply what’s being offered to us; we avoid any doubts by being in complete control of what we are feeding our firearms.

Apples & oranges

To protect their products from being too-easily copied, manufacturers of commercial ammunition—or any other product, for that matter—are understandably reticent about the details. Military, of course, are even more close-mouthed about their internal workings. That combination leaves us comparing apples to oranges in our examination of .223 Rem vs 5.56 NATO pressures.

However, independent side-by-side testing and comparison of .223 Rem and 5.56 NATO by shooting industry manufacturers and curious amateurs—the latter using strain gauges attached to the chamber area of rifles—have concluded that 5.56 NATO cartridges generally produce approximately 60,000psi when fired in a .223 Rem chamber and 55,000psi in a 5.56 NATO chamber.

Why no 5.56 load data?

Checking a sampling of load data manuals—Berger, Hornady, Lyman, Sierra and Speer—showed loads listed for the .223 Rem and none for the higher pressure 5.56 NATO, though Speer combined the two cartridges under one heading. Among online loading manuals checked, only Nosler lists 5.56 NATO separately, but the loads (at least for 69-gr. bullets) are an identical copy of their .223 Rem loads, which are comparable to the loads in the other manuals.

Hodgdon and Lyman are more helpful in including pressures for their minimum and maximum .223 Rem loads, providing some basis for comparing loads among the manuals to conclude they all do appear to be at SAAMI .223 Rem pressures.

The lack of 5.56 NATO load data isn’t surprising, as virtually all industry manufacturers warn against shooting the higher pressure NATO cartridge in .223 Rem chambers. Load data for genuine, higher pressure 5.56 NATO is out there on the Internet, but from experimenters, not manufacturers. While experimenting with 5.56 NATO is within the realm of the advanced, cautious handloader, the beginner should first get plenty of experience and comprehensive knowledge before dabbling in it, and then take redundant precautions to prevent inadvertently shooting the 5.56 NATO in a .223 Rem firearm.