By Jim Dickson | Contributing Writer

Cryogenic treatment of firearms yields unbelievable advances in accuracy and durability.

Scientific studies have shown an increase in the life of treated parts of more than 600% on the average with some types of parts less and others up to 1000% longer life. Accuracy is increased as is velocity and cleaning becomes a breeze.

All of these miracles come about through the cryogenic treatment process where the disassembled firearm is cycled to 300 degrees below zero and then back to 300 degrees above zero. There is no contact with liquid nitrogen which could cause cracks. This process relieves all the stress in the steel that causes gun barrels to walk their shots as they heat up thereby greatly increasing accuracy.

During this process remarkable things happen to the steel being treated. The soft austenite crystals that did not turn into the harder and tougher martinsite crystals during heat treatment make the transition to martinsite. It is far harder to gouge out a martinsite crystal during abrasion and wear than it is to gouge out an austenite crystal. The pores of the metal are filled by the fine precipitation of carbide particles which greatly enhance the strength and toughness of the martinsite matrix. Previously the pores left a foot hold for wear and abrasion to dig in and tear microscopic chunks out of the metal. It is now a solid smooth surface that is much harder for an abrasive particle to dig into and plow a furrow.

This extra smoothness reduces bullet drag and results in an average increase of velocity of 50-60 FPS.

Formerly, these pores held all manner of powder fouling in guns and caused the cleaning process to drag on and on as more gunk was bled out of these pores by the bore cleaner. Now the first patch comes out pushing the fouling like a wad, the second patch is nearly clean and the third patch is clean on my cryogenically treated barrel. It’s like cleaning a piece of glass instead of metal.

For the custom rifle maker there is another advantage. Because of the filling of the microscopic pores, the metal will now take up to a 50 percent greater polish. That can really make a gun stand out if you are willing to invest in the finer grit polishing compounds that you can now take advantage of.

Gunsmiths trying to get the best trigger pull possible can also take advantage to this improvement to the metal.

There are certain things to be noted. While cryogenic treatment of shotgun barrels improves the patterns, the soft solder used on some doubles can’t take the 300 degree above part of the cycle. Additionally, springs should be treated separately because if they are under tension when treated the strength of the spring may sometimes be increased or decreased by the treatment. Treated while not under tension produces spring life far in excess of what it originally was. If you treat all the parts of a Model 1873 Colt Single Action Army revolver it will hold up alongside the best modern coil spring single actions.

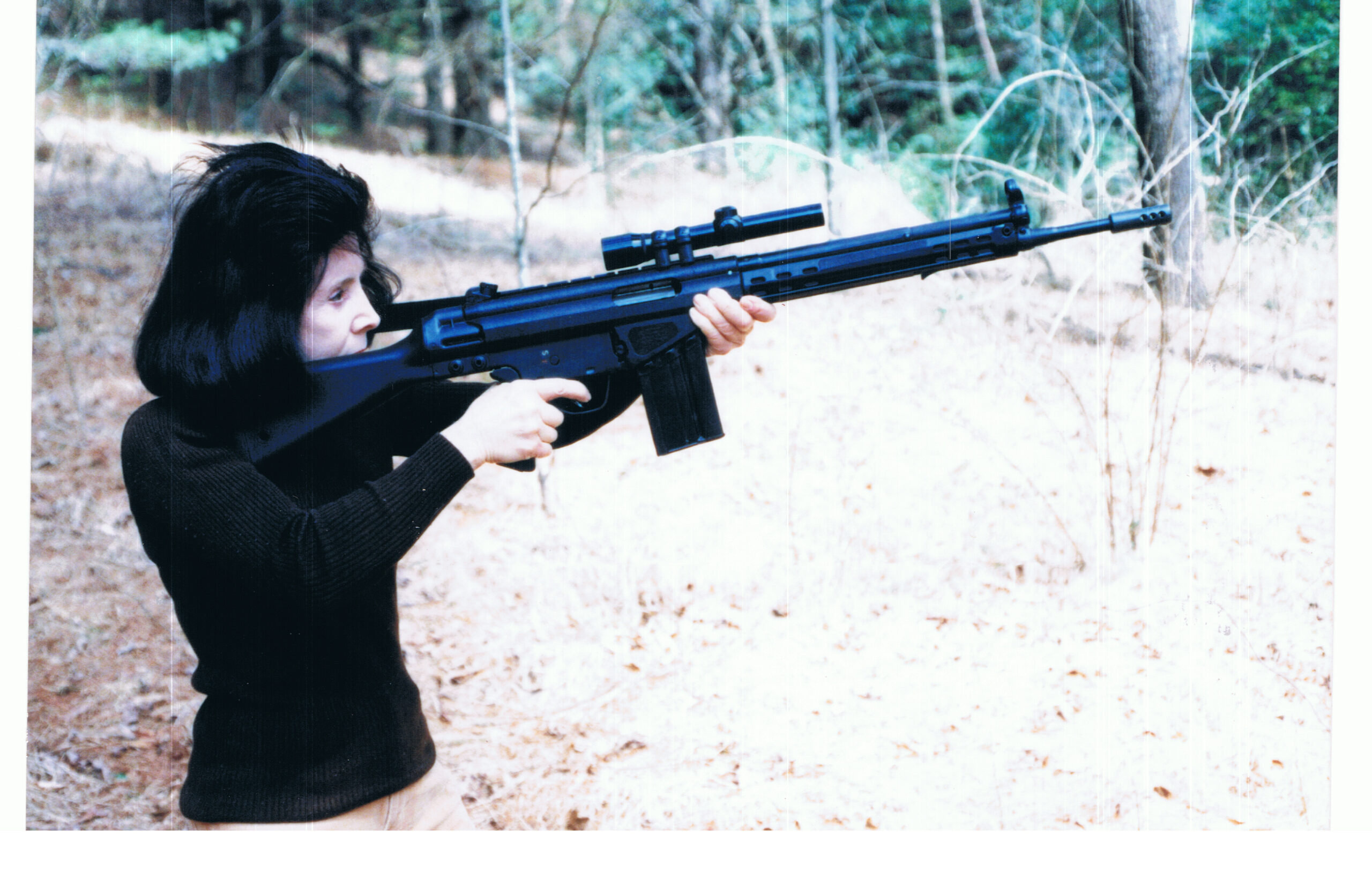

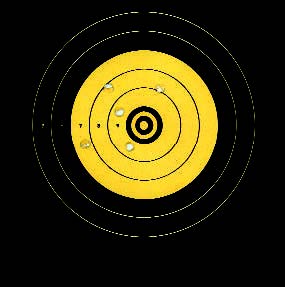

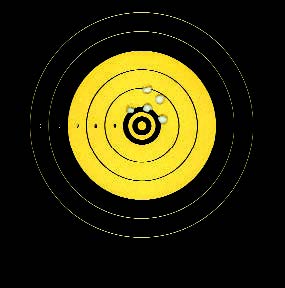

Some years ago I was testing a Century Arms Centurian 99 semi-auto built on a G3 parts kit. I wasn’t happy with the accuracy so I recrowned the barrel, put in a newer, tighter bolt, and had the barrel cryogenically treated. What a difference! The light barreled rifle would only shoot ¾-MOA groups now! It didn’t matter whether it was a cold barrel or a barrel so hot that the oil was smoking; always ¾-MOA.

Incidentally, the flash hider on that rifle was made of the most porous steel I ever saw. I had to just swish it around in a jar of gasoline to get all of the fouling out of the pores as it was virtually impossible to clean otherwise. After cryogenic treatment it cleaned up like it was made of glass, just like the rest of the barrel.

Cryogenic treatment of heat treatable aluminum alloys also works wonders at increasing wear resistance, strength, and high temperature properties. The microstructure consists of silicon rod precipitates, which give the alloy strength, in an aluminum matrix. Cryogenic treatment increases and refines silicon rod precipitation formation.

While some companies like J. P. Enterprises, makers of super accurate AR-15 and bolt action rifles, have embraced the new technology, the bulk of cryogenic customers has always been the end user.

America is the home of planned obsolescence and most factories are not interested in improving the life of their products. When a factory calls it is generally because they have a part that keeps breaking or wearing out and they want it fixed so that it will last. It is the same with steel. Double vacuum re-melt steel (steel that has been melted twice in a vacuum) has been around for decades and is as big an advancement in steel purity as crucible steel was over blister steel, yet you never see guns made from it. The cold hard fact is that most factories only want their products to last as long as their competitors. You saw that in cars when 100,000 miles was the life of a car until the Japanese raised the bar. Many years before that happened I remember talking to a Chevrolet car designer who told me that they made their cars to last 50,000 miles for the first owner and another 50,000 miles for the second owner and if the car lasted past 100,000 miles it was just your good luck. That sure explained all the trouble that I was having with my 1950 Chevrolet at that time. They want things to wear out so that you will have to buy a new one.

The moral is don’t wait for the big companies to start doing it first. They use cryogenics on troublesome parts in their factories but not in the products they sell the public. However, you can go ahead and have it done to anything you desire. The company that I recommend is:

Diversified Cryogenics

2180 County Road 42 West

Burnsville, Mn 55337

Mark Link runs this company and he is very friendly and accommodating to gun owners.