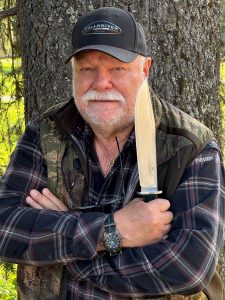

By Jim Dickson | Contributing Writer

In the past I have written about the best factory made knives in the low to medium price range.

Now I will tell you about a knife that was made to be the best that they could produce without regard to the price: the Swedish Fallkniven Modern Bowie.

Designed to be the most indestructible survival knife possible, this is a no frills and gimmicks honest survival knife put out by a Swedish hunter and woodsman who has killed over 70 moose in his lifetime. There are no saw teeth to form stress risers and cause it to break. No cold and uncomfortable hollow handles to break off. Just a plain, honest tool for serious work.

Company owner Peter Hjortberger has an office in town but lives deep in the woods where moose and bear are regular visitors. A lifelong hunter and woodsman, he has used knives deep in the woods enough to know what is needed. That alone sets him apart from most knife makers as does his policy of making the best knife he can first and pricing it second. Unlike some knife makers he makes sure that there is a proper radius instead of a sharp corner 90 degree angle which can act as a stress riser and cause breakage at the junction of the blade and tang.

The shape is the same as many of the Viking sax blades. This size and basic shape has remained in continuous production since long before the Vikings and may be seen in Solingen Bowie knives as well as many of the Bowie knives used in the U.S. in the heyday of the Bowie knife in the 19th Century.

It is a 10 ¼-inch blade, ¼-inch thick, 1 ¾ inches wide, and 15 ¼ inches over all. The knife weighs 1 pound 5 ounces. Balance point is about 1 ¼ inches in front of the guard.

Intended as a survival knife it is balanced for chopping wood. This is the defining test of a true survival knife. Everything you make in the wilderness is made of wood. Ten-inch blades are the smallest that really work here. Smaller knives that don’t chop wood as well really stack the deck against your survival. There aren’t enough hours in the day to whittle through all the wood you are faced with cutting. You have to be able to chop effectively. This rules out small knives. This is why natives worldwide use big wood cutting knives whether they be Philippine bolo knives, Gurkha kukris, or South American Machetes. Even the Eskimos in the treeless frozen arctic need a big knife to cut snow blocks for their igloos. No matter what part of the world you are in you need a big survival knife if you are going to be in the wilderness.

Like almost all knives, the false edge is not sharpened. I have found a sharpened false edge highly useful at times and wish that they were always sharp. The blade came shaving sharp with a proper convex grind for strength. There is a fine satin finish on the blade and both fit and finish are immaculate

There is a stainless steel guard 2 5/16 inches long and 3/16-inch thick. I would have preferred a wider guard of 3 ¼ inches but at least it has one.

The knife utilizes the traditional Scandinavian three-piece lamination of a hard core sandwiched between soft iron only in this knife all three pieces are stainless steel. The core is CoS steel at a Rockwell hardness of 59.5 on the Rockwell C scale. The composition of CoS steel is 1.05% carbon, 16% chromium, 1.5% molybdenum, 2.5% cobalt, and .25% vanadium. You can see the demarcation line between the layers running about a ¼ inch above the edge running down the blade if you look close.

The side steel is almost totally free of carbon. It is 420J2 composed of a mere trace of carbon at 0.15-0.36% and 14% of chromium. It’s Rockwell hardness on the C scale is 55.

The blade is convex ground for strength. This is also called a saber grind because swords used it. It requires hand work to do properly so it is not as common as it should be.

Fallkniven took five knives and attempted to break them. Only one broke. They were totally unable to break the other four. The knives sprang back to shape after bending until they bent one 90 degrees and it only sprang back partly. This is the kind of performance that you want in a survival knife because if your knife breaks you probably won’t survive. The Eskimos have a saying. “With a knife you can survive. Without one you die.” This is no place to skimp on costs. After all. What is your life worth?

The handle is made of thermorun, a plastic that does not dissolve when it meets Deet insect repellent.

As a former Alaskan bush dweller I can tell you that is really important. The number of mosquitoes in a square foot of air is truly daunting in these latitudes. It is a good firm non-slip material with fine checkering on its sides and a fore finger notch next to the guard. It does not interfere with the classic Bowie knife fighting grip with the edge up. The sides of the handle are contoured for a comfortable grip. The tang goes all the way through the handle and out the back where the exposed portion measures ¼ by ¾ inches. You don’t have to worry about this tang breaking.

There is a stainless steel lined lanyard hole at the back of the handle. This can be especially valuable for people working around water where to drop something may be to lose it forever.

The scabbard is made from very heavy leather with a substantial stitch guard and double stitching. Total thickness is 5/8-inch. There are two eyelets for tying down the scabbard at the bottom and a wraparound safety strap next to the guard to keep the knife in the scabbard.

This knife seems very familiar to me as I have used 10 inch Bowie knives since the late 1960’s. In my blacksmith shop I made duplicates of the Resin Bowie presentation knife to Edwin Forrest in Robert Abels book “BOWIE KNIVES” and I carried one when Betty and I were living in a one room log trapper’s cabin deep in the Alaskan interior.

All the knives that Jim Bowie and his brother Rezin gave to their friends matched the description of the knife Jim Bowie used at the Vidalia Sandbar fight, a Spanish dagger or a butcher knife. This last one took those knives and matched the description of the improvements James Black made to the knife, a clipped point and a double guard. The stag handle was of a particularly Scottish type and the Bowie family originated in Scotland. I know from years of using just how well this design works in the woods.

Fallkniven makes other knives with the traditional Scandinavian three-piece lamination as well and here are three other models. All three have rudimentary guards formed by the handle. I would prefer a proper guard between the blade and the handle but the tradition in Scandinavia is for knives without guards as they like the dangler style sheaths that come up halfway over the handle and these don’t hold the knife as securely if there is a guard.

All three knives feature the tang that goes all the way through the thermorun handle.

The first of these is the F1 pilot’s knife originally made for the Swedish Air Force. Since a Swedish fighter pilot bailing out may encounter 9G’s of force they wanted the lightest knife possible. The result is the F1. A 5-ounce, 4-inch blade, one inch wide, 1/8-inch thick knife that is 8 ¾ inches overall. The plastic sheath features a unique sheath lock to make sure the knife withstands the G forces it may encounter when a pilot bails out. A simple lever either locks or unlocks the blade.

This is a better companion to the big MB Bowie than a folding knife for it is far stronger and cannot fold on your fingers as when the lock on the lock blade folder fails. People usually don’t realize just how little pressure it takes to force one of these lock blade folding knives shut.

Back when Betty and I were in Alaska there was a man working on a frozen moose carcass chipping away at it using a big name folding lock blade knife as an ice pick. The first hard blow that didn’t land just right and the knife closed. Hard. It took off all his fingers on that hand.

I never looked at folding knives the same way again after hearing about that. If he had been using an F1 knife with his thumb over the butt of the knife he would have been all right. Still better, he should have been using an axe or a saw like everyone else faced with that job would use.

The F1 is a tough knife. In tests at the Technical University of Lulea in Sweden it took 195 pounds of sideways pressure to break the 1/8-inch thick F1 blade. Unlike many similar knives the F1 is convex ground for strength and will not chip easily like hollow ground blades do.

This knife came about because the Swedish pilots didn’t like the fact that they were issued knives that only cost a few dollars. They thought they were worth more than that. The Swedish Air Force listened to Peter Hjortberger because he was known to be an expert woodsman who had lived in the woods since childhood and understood wilderness survival. Nevertheless it was still a hard sell before they gave in to the pilots and spent more money on the pilot’s knives.

For someone wanting to split the size difference there is the A1 army knife. This is a 6 5/16-inch blade, 1 & ¼ inch wide, just under ¼ inch thick blade that weighs 10 ½ ounces and is 10 7/8 inches overall. This size blade is the easiest for the average man to learn to use effectively as a hunting knife. It feels right in the hand and is easy to control. It makes an excellent all round hunting knife. At the break tests it took 556 pounds of sideways pressure to break this robust knife.

The last knife that I evaluated is the S1. This is a 5 ½-inch blade, 1 1/8 inches wide, 3/16-inch thick, weighing 6 ½ ounces and 9 7/8 inches over all. A smaller and lighter version of the A1 still will work fine as a hunting knife for most chores. For me, the A1 feels and handles better but a smaller man might prefer the S1. The S1 took 367 pounds to its side before breaking. For anyone wanting a small tough lightweight knife for deer hunting look no further.

Fallkniven offers a regrinding service if you ever need it and they can also replace a damaged thermorun handle if a porcupine decides to chew on yours or something. Porcupines have ruined many an axe handle and other items that had sweat on them by chewing when they had the chance.

Fallkniven makes some of the best factory knives available. Their U.S. Distributor is:

Blue Ridge Knives, Inc.

314 Lee Highway

Marion, VA 24354

276-783-6143

www.brk.com