by Art Merrill | Contributing Editor

I’ll admit here that I have no brand loyalty. Every maker of handloading tools and components believes he has made the better mousetrap; if I agree and the price is right, he gets my money. Sometimes I inherit somebody’s old tools and I use them because they work well enough that my frugal nature prevents me from needlessly replacing them with something newfangled. Most handloading tools are great values because they last so long that, unlike personal computers and appliances, they are one-time, lifetime purchases.

Press time

I’m a devout believer in the full-size, single stage “O” frame press, which may be the last indestructible product on the planet that has a moving part. No matter who manufactures it, the full-size “O” frame press is true heavy metal and pretty much bomb-proof. I have been regularly using the same RCBS Rock Chucker “O” frame press for 30 years without a single failure of any kind. The only maintenance such presses require is an occasional wiping down of the ram with a lubricating oil.

I recommend the single stage “O” frame press for other reasons as well, especially for the beginning handloader. A “C” frame press—both frames named for their resemblance to those letters—is structurally weaker than the “O” frame press, and at least theoretically can flex when applying a lot of force when sizing larger cases. If that theory is true, then it seems logical that the turret presses with their rotating heads could also flex, plus they have another moving part for Murphy to get into, as do those presses with removable tool heads.

That said, the smaller “O” frame RCBS Partner Press and “C” frames like the Lee Precision Reloader Press are still good quality, and their low price makes them an ideal choice for the beginner who isn’t sure how deeply he may be interested in handloading and so wants a minimum cash investment. MSRP on the Lee Reloader is only $40; RCBS offers its small “O” frame Partner in kit form with the Speer Reloading Manual, a scale, lube, loading block and a handful of necessary tools for $100 MSRP. For less than twice that – MSRP $186 – you can get a similar Lee kit with a full-size “O” frame press. If you’re sure of your interest, the next price step up in excellent “O” frame kits is the Redding Big Boss kit for $295 MSRP and the Lyman Crusher kit for $300 MSRP.

Progress from the “O” frame

Progressive presses that perform all the loading operations—depriming, resizing, priming, charging, bullet seating and crimping—with every pull of the handle are fantastic tools for high production handloading, but life is full of trade-offs and so are progressives; they have enough disadvantages that I believe the beginning handloader should not start with them. With so many moving parts that must be in time with each other, the Murphy rule applies many times over; lacking single stage loading experience you may have difficulty troubleshooting problems; they require precise adjustments and readjustments; you must pay extra attention to prevent double charging or squib loads while simultaneously focusing on other operations; and to get that rapid, high volume reloading, you will skip the primer pocket cleaning. They are also five to eight times more expensive than a single stage “O” frame press.

I suggest loading 1,000 rifle and pistol cartridges on a single stage “O” frame press first to gain experience and knowledge before advancing to a progressive reloading press. If eventually you do buy a progressive, you will still be using your single stage “O” frame press for other cartridges and tasks (like swaging primer pockets in milsurp brass).

Take your pick

Again, pick whatever make of “O” frame press pleases you; most “O” frame single stage presses have 1¼” x 12 threads with an insert already installed that accepts standard 7/8” x 14 dies. Larger cartridge cases, such as the .577/450 Martini-Henry and .416 Barrett, require larger dies with larger 1¼” x 12 threads; simply remove the press insert to use the larger dies. If you think you may one day want that option for loading larger cases, be sure your press of choice has that insert.

Let’s compare a few presses. At this writing the Hornady Classic Lock-N-Load™ press is the least expensive full-size “O” frame press, but utilizing its Lock-N-Load™ feature requires purchasing separate die bushings at $11-$42 per set of three for every one of your die sets. The Lee Precision Classic press is next up in price and is easily converted to left-hand operation; so is the Lyman Crusher. If you buy the RCBS Rock Chucker Supreme, you can later buy the RCBS Piggyback unit that converts it to a progressive reloading press for waaay less than the cost of a new progressive press. Redding has a deserved reputation for quality that comes with higher price tags. All of these quality presses include a primer seater, all take universal shellholders—and all of them will outlive you.

Shellholders

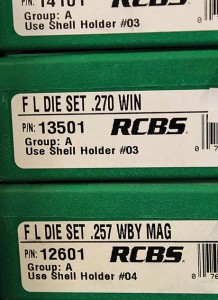

You need a way to fix the cartridge case to the press ram, and you accomplish this by use of a shellholder. All of the above named presses (in fact, with few exceptions all presses) accept “universal” shellholders. They are universal in that a shellholder from one maker will fit the ram on another maker’s press. They are not universal in their numbering; meaning one maker’s size #3 shellholder is not necessarily the same as another maker’s size #3 shellholder.

This shellholder that snaps into place atop the press ram is specific to one or more cartridges because it must fit the case rim snugly to draw the resized case back out of the die. A shellholder too small will not accept the cartridge case rim; one too large will leave your case stuck in the resizing die and mangle the case rim as you lower the ram.

Individually packaged shellholders will indicate on the package what cartridge cases it fits, or the maker’s accompanying chart will cross reference the shellholder number to the cartridge cases that fit it. Some reloading die sets come with the proper shellholder; if not, the label on the die set packaging should tell you what size shellholder from that manufacturer you need. Some makers sell complete sets of shellholders organized in storage containers so that you don’t have to buy them piecemeal.

Next month’s topic in this year-long exploration of beginning handloading examines reloading dies.