By Mike Nesbitt | Contributing Editor

Usually when paper patching is discussed it is seen as a two-wrap process.

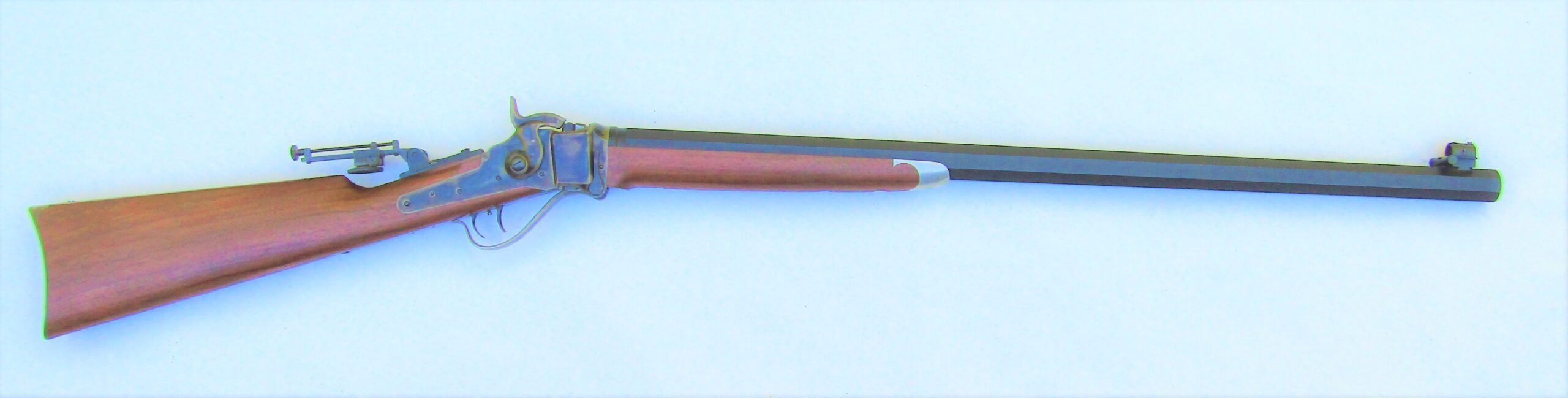

The only shooter I know of who ever mentioned triple wrapping was Elmer Keith and he had some bullets which he used in his old original Sharps .44/90 with three wraps of paper. (We’ve all learned a lot from Elmer.)

Several years ago, I used a 500-grain bullet in my .50/90 with three wraps and in that gun the triple wrapped bullets seemed to perform better than the same bullet with only two wraps. What kind of paper I was using back then, just over 40 years ago, I can’t recall but that was some of the paper bought from C. Sharps Arms in the small tablet. My loads for the .50/90 were mainly for hunting and very few of them were ever shot at paper targets.

Recently I’ve gone back to triple wrapping due to one particular bullet. That bullet is cast from a KAL mold for the .44/77 and the tapered ‘slick’ drops from the mold with a diameter at the base of .432”. Over the few years that I’ve had that mold, the bullets from it have never given me the performance that I wanted. However, it did come close, close enough that I kept on trying.

Interest in shooting paper patched bullets came to a new peak after I dismantled an old factory loaded .44/77. That old round had a bullet which weighed 405 grains and it had a diameter at the base of .438”. With this information, I wanted some .438” bullets. Rather than buy a new mold, which I might still do, I checked to see if Buffalo Arms offered their swaged bullets in that diameter. They do! I was just about to order 50 or 100 of those when I thought to check, seeing if I already had some of those bullets. I did!

So, ten of the Buffalo Arms .438” bullets were patched with two wraps of the paper which is also sold by Buffalo Arms. That paper, according to my micrometer, is about .002” in thickness and two complete wraps with that paper takes a .438” diameter bullet right up to .446” which is “spot on” for the .44/77. When those bullets were fired, they showed an instant improvement over the .432” diameter bullets with the two wraps of paper.

Then I remembered Elmer Keith and his triple wrapping of paper patched bullets. Some thought followed, three wraps of the paper around the .432” bullets would take their diameter up to .444”, almost the same as the patched .438” bullets. Within minutes, some triple patching was tried.

First a patch template had to be made. Making a patch template is easy and I make them out of cardboard, the stiff cardboard that is commonly used as tablet backing. To find the length, simply multiply the caliber (.44 in this case) times pi (3.14) times 3 for the three wraps. That comes out to just over 4 1/8”. I like to make my cardboard patch templates just a little too long so they can be trimmed to size after seeing how well the patches fit the bullets. The angle on the ends of the template were copied from a steel two-wrap template that I had bought, most likely from C. Sharps Arms.

That length, of course, is for each of the parallel sides. Don’t cut a rectangle to length and then cut the end angles, the result will be terribly too short. Cut the cardboard longer than needed to begin with, perhaps a 1” wide strip. Then cut the angle on one end. With that cut, measure the needed length, just over 4 1/8” in this case, and then cut the angle on the other end. This will give you the template for triple patching.

Then, if the patches are too long, trim the template with a sharp pair of scissors. On the other hand, if the patches are too short, just make a slightly longer template.

Cutting the patches while using the long or triple-wrap template is no different than how you might be doing it with the double-wrap template. My way is to cut the sheet or sheets of paper into strips 7/8” wide and then simply cut the patches with sharp scissors while using the template as the guide for both length and angle. This method gives me a good supply of cut patches in a rather short period of time.

Applying the triple-wrap patches is, likewise, not really any different than applying a double-wrap patch, it is only longer. I do use the ‘wet patch’ method of wrapping and I simply start the patch on to the bullet, about where it should be, hold the trailing part of the patch out at about 90-degrees, and begin to roll it on. The rolling is continued down my finger until the wrapping is completed. I have tried using a patching board but my old habits of patching by hand seem to prevail so I will continue to do so.

After drying, the triple-wrapped bullets are loaded into the sized, primed, expanded, and charged cases. In the .44/77, the amount of powder I’ve been using is 75 grains of Swiss 1 1/2Fg which requires very little compression. Compression is simply done with the expander die, backed off so compression is not too deep. The powder is then compressed under a Walters’ wad and then the cartridge is ready to receive the lube cookie and bullet. The triple-wrapped bullets are still easily seated over the lube cookie with just fingertips. After the bullet is inserted, deep enough to give the cartridge an overall length of about 3”, the same as the old factory loads, it is simple pressed down by hand to assure that it is resting on the lube, and then the cartridge is run part way into a file trim die to straighten the mouth of the case, which had been slightly funneled by the expander die. With that, the load is ready for shooting.

And the groups with the .44-77 did tighten which was very pleasing. But that made me quickly turn to another rifle in another caliber, my favorite .50-70. Would a triple-wrapped patch help or improve my targets with that rifle too?

That question was answered just as soon as I could cast more bullets, from another KAL mold adjusted to drop the .50 caliber Sharps’ design bullets at 473 grains, with a diameter at the heel of .498”. Those bullets are already larger in diameter than what is often recommended for the .50 caliber Sharps but I felt it would still be a very good try just to see how things would work. So, another patch template was cut out of cardboard, to cut triple-wrap patches for the .50 which are over 5” long, and the batch of bullets was soon patched and ready to load.

Swiss 1 1/2Fg powder was called upon again, with 63.0 grains of it being loaded into the prepared and primed 50-70 cases. Over the powder went an .060” fiber wad from John Walters before the powder was compress to make appropriate room for the lube and bullet and then the grease wad, or lube cookie, of just over 1/8” was added on top of the wad. Following that, the triple-wrapped bullets were pushed firmly down on top of the lube and then the loaded rounds were run through the taper crimp die. That was all done fairly fast but let me admit that I had loaded only two rounds, mainly with the idea of seeing if those would chamber without any problems.

They did chamber with no hesitation. Then, at my very next trip to the range, those two cartridges were kept separate from others. After doing some shooting with the .50-70 and identifying where those bullet holes were on the target, the rifle’s barrel was swabbed and the two shots with the triple-wrapped patches were tried. First one was fired, then the barrel swabbed again before the second one was fired. One reason for wiping the barrel between shots is because if the added thickness of paper patching left a “paper ring” at the end of the chamber, the second round might be prevented from entering the chamber completely. I found no evidence on the cleaning patch of a paper ring and the second round chambered easily.

That second shot hit the target just a fraction of an inch away from the first round fired with the triple-wrapped paper patch. Very encouraging. Those two shots were a bit high and to the right, so a sight adjustment was made while looking forward to shooting more of the triple-wrapped bullets in the .50-70.

More of the triple-wrapped paper patch loads were prepared for the .50-70 with the same loading as mentioned above. Those went with me on my very next trip to the range where they were fired at a 100-yard target, from the bench, while wiping the bore between shots. The results were very pleasing to me and, at this time, I do believe this load will be used in some “buffalo gun” competition which isn’t very far in the future. The 5-shot group measures 2 ½” and I certainly hope this rifle, with these loads, and this shooter can do it all again.

Now I’ll be using triple-wrapped paper patched loads more than ever, especially with both the .44-77 and the .50-70 Sharps. Don’t be surprised if I follow more on the trail Elmer Keith was on and use triple-wrapped patches in the old .44-90 Sharps too.