By Art Merrill | Contributing Editor

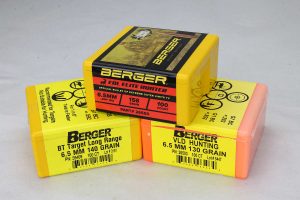

(L-R) 130-grain Hunting and 140-grain Target VLDs preceded the hybrid 156-grain EOL Elite Hunter.

“Tangent, “secant” and “ogive” are terms of geometry, and most handloaders are less interested in mathematics than they are in getting enjoyment from their hobby and performance from their firearms.

While we don’t need to use complex formulae, cartridge ballistics is a science, not magic or luck, and it aids our success to understand the principles behind our practices.

Not all handloaders are concerned with tangent or secant ogives; how often do you hear someone use the terms when discussing pistol bullets? A great many handloaders are satisfied with accomplishing their mission of adequate cartridge performance without delving into the more technical “whosits” and “whatfors” of bullet geometry. “Tangent” and “secant” ogive are terms that have been the purview of the precision rifle target shooter, but these days they are more frequently becoming the lexicon of rifle hunter handloaders who look to extending their range.

Ogive radius

When we speak about a bullet’s ogive, we often refer to that part of the bullet back from the tip that reaches full diameter, the part that first contacts the rifling, the beginning of the shank or bearing surface. However, more properly the ogive is the entire forward part of the bullet, extending from the tip to that full diameter point at the start of the bearing surface, and it is measured in length of radius.

Imagine laying a bullet on its side on a piece of paper. Using a drafter’s compass and starting at that “ogive” point on the bullet that first reaches full diameter, trace a path along the bullet edge to the tip, and then keep on tracing past the bullet until the compass makes a full 360-degree circle. The size of the circle, the radius, is the radius of the bullet’s ogive. Now imagine cutting that circle and laying it out as a straight line; we now have the length of the radius.

“Tangent” and “secant” have specific definitions in geometry, but for our illustration here, a bullet with a tangent ogive has a shorter radius than a same caliber bullet with a secant ogive. What we get with a secant ogive is a bullet with an exaggerated nose length, appearing rather like a 1950s sci-fi spaceship without the fins.

Tradeoffs

Secant ogives are comparatively new in the overall history of bullets, with ballistician Brian Litz of Berger Bullets and Applied Ballistics at the forefront of their shooting sports development.

Berger Bullets evolved VLD offerings from precision target shooting to hunting. A further evolution has culminated in a hybrid secant-tangent ogive bullet in an unusual 6.5mm 156-grain weight.

Their advantage over tangent ogive bullets is their lower drag that gives secant ogive bullets superior ballistic coefficient (BC), which results in greater velocity retention over distance. They can also provide greater precision over long range, which is why many Long Range competition shooters have gone to secant ogive bullets. In a world of tradeoffs, however, their downside is that secant ogive bullets like Berger’s VLD (Very Low Drag) are quite sensitive to bullet seating depth, which determines how far a bullet must “jump” from the cartridge before the bearing surface (that “ogive” we typically refer to) engages the rifling.

I’ve experienced a variance of three thousandths of an inch in bullet seating depth/cartridge overall length significantly opening up group size with VLD bullets. That sensitivity also means that case trimming must be quite exact. Especially in heavier weights, such bullets tend to be quite long for caliber, which means they often must protrude further into the case and take up powder space in order to fit in a rifle magazine. For these reasons, the secant ogive bullet has not seen a widespread application in hunting handloads.

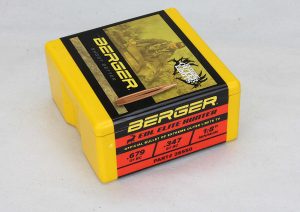

Berger’s 6.5mm 156-grain hybrid boasts a superior BC for a hunting bullet.

The more common tangent ogive bullet doesn’t have that seating depth/cartridge overall length sensitivity because its ogive tapers less abruptly to the bearing surface, allowing the bullet to somewhat “self-center” in the rifling. But its BC and long range precision are inferior to those of secant ogive bullets.

What if there were a way to get the best of both worlds, long range performance and forgiving seating depth? Brian Litz found a way in creating a hybrid design that incorporates the advantages of both tangent and secant ogives. After considerable success with the VLD design for competition, Berger Bullets introduced their VLD Hunting bullet of their secant ogive configuration constructed with terminal performance – expansion in the soft tissue of game animals – in mind. As good as they are, that sensitivity to seating depth requires handloaders of hunting ammo to load with the skill and tools of precision target shooting reloaders.

New weight for 6.5mm

This summer Berger announced release of a new bullet in their hybrid EOL (Extreme Outer Limits) Elite Hunter line, a 6.5mm in an unusual weight of 156 grains. Perhaps the most-used bullets of 6.5mm are those of 140 grains and 160 grains, though there are lighter weights, as well. The singular 156-grain weight is likely a necessary condescension to the hybrid design. Still, if we load and shoot it as a 160-grain bullet, we should be pleased with its performance.

Without yet having done either, first thoughts are that, though 160-grain 6.5mm bullets are suited for bigger game – Scandinavians have been bagging moose with the 6.5×55 Swedish cartridge for more than a century – Berger’s new 156-grain bullet may shine brightest in extending long range shots at smaller American critters like pronghorn and coyote. The EOL Elite Hunter’s hybrid design should theoretically maintain the bullet’s velocity over longer distance; velocity needed to ensure bullet expansion when it arrives on target. It should also shoot a flatter trajectory than a tangent ogive 160-grain 6.5mm bullet. Will it? Some quick preliminary fiddling with ballistic programs will answer theory.

Bullet 400 yd drop 500yd drop 800yd drop BC (G1)

Hornady RN Interlock -36” -75” -344” .283

Woodleigh spitzer -27” -55” -214” .509

Berger EOL Elite Hunter -25” -50” -184” .679

Few 160-grain bullets to compare

Among major American manufacturers Sierra, Speer, Hornady, Nosler and Berger, only Hornady lists a 160-grain 6.5mm bullet, their round nose (RN) Interlock. Among foreign makers, Woodleigh of Australia has a 160-grain spitzer type hunting bullet. Running all three bullets through a ballistics calculator program, inputting a 2,540 fps muzzle velocity from the .260 Remington cartridge as garnered from available load data, and starting with a 200 yard zero, results appear in the accompanying table.

The ogive of the 156-grain EOL Elite Hunter (center) is a hybrid of the secant (L) and the tangent (R) ogive bullets.

As we’d expect with its higher BC, the flat trajectory advantage goes more and more to the Berger bullet as the range increases. But as with most good things in life, however, getting long range precision from this long range bullet comes with a caveat: minimum recommended twist is 1:7.75 inches. Twist rates for most American production 6.5mm/.264 rifles is a fairly standardized 1:8 or 1:9; foreign guns, too, generally have slower twists, if my own foreigners sporting 1:8.5, 1: 8.75 and 1:9 twist rates are any example (the 6.5×54 Mannlicher-Schoenauer is an exception with a 1:7.5 twist).

We can theoretically compensate a bit for slow twist with a higher muzzle velocity and, indeed, Berger’s online Twist Rate Stability Calculator gives the 156-grain EOL Elite Hunter bullet a grade of “Marginally Stable” when launched through a 1:8 barrel at the above-mentioned 2,540 fps – achieved with maximum listed 160-grain bullet loads in the 260 Remington. Running 6.5 Magnum cartridge loads through the calculator fared no better. Clearly then, unless we want to dance along the edge of utilizing maximum loads with their attendant concerns, then we need a 1:7.75 or 1:7.5 twist barrel to take full advantage of Berger’s new bullet – or any 160-grain 6.5mm bullet, for that matter.

The calculators and the math support the hypothesis of the improved performance in Berger’s EOL Elite Hunter secant-tangent ogive hybridization. As handloaders, it’s our turn to test theory by practice. Based on Berger’s reputation for precision, it’s a good bet a lot of hunters will be pleased with their own results.